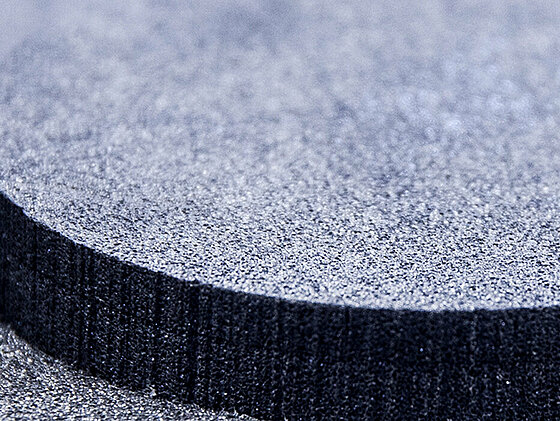

We offer customised foam.

In addition to the foam equipment for our transportation containers, we also produce foam parts for various industries and companies.

Use the advantages

The advantages of Thermodyne's production are revealed in terms of outstanding economic efficiency. Our customers do not have to invest in their own production capacity. In addition, our targeted and expert advice saves valuable development time. And through goods logistics, which we offer in addition to manufacturing, additional potential can be exploited in the field of transportation costs and reliable delivery.

TCS mats are so-called shadow boards, i.e. two-colour foam with contour-accurate cutouts for tools, devices and even whole components. Our services include the digitisation of components, different visual appearances of the foam surface, logo laserings (which are possible) as well as sunken, lasered signs. The digitisation of the objects can take place on request at your place.

Upon request, we are able to hold special materials in stock for you and, as the case may be, special dimensions. From this, different thicknesses can be freely retrieved. These include PE and PU foam boards, Ethafoam, Polylam and sponge rubber from Alveo or Plastazote as either closed-cell fine-pored or closed-cell block foam. In addition to black and anthracite, the panels are also available in white, yellow, red, blue, green and grey. They are also antistatic, electrically conductive and available for short-term production.

Inserts for boxes and carrying cases are either provided by Thermodyne in accordance with the customer’s specifications or designed and manufactured by us for the specific application. Even if, for example, different types of foam have to be used for an optimum solution, we can easily implement this thanks to state-of-the-art production facilities. For long-lasting and durable installation, we use special, low-odour adhesives which, upon request, are available from us.

Foam product carriers, which store products such as eyewear, watches or beauty products at the point of sale or during presentations, are becoming increasingly popular. In our own production facilities, we are able to create optimum foam blanks and graphic coatings. For the latter, we also take care of the printing of graphics files.

Do you need foam parts in order to complete a solution in-house? With Thermodyne, it’s no problem! We manufacture foam parts by order, according to customer data such as technical drawings, CAD data and 3D models e.g. Step or IGES, depending on the material specification. By outsourcing these services, you save on investment in terms of your own production facilities and you also benefit from our efficient production processes.

Products that

bear your

signature

In the case of Thermodyne products, the special and individual does not just end with size and features. We are able to offer you almost unlimited possibilities for the customisation and branding of your solution. Together with you, we look at how we can introduce additional functions and real added value to your products. Many of our satisfied customers are enthusiastic about these unmistakable solutions.

Are you looking for an optimum trolley container for your goods and products? If so, with our experienced team of consultants, you have come to the right place!

Phone: +49 (0) 541 181 4997 - 92

friedel.denter@thermodyne.de